Introduction & Background

Oilfield extraction sites are typically located far from population centers and have distinct power usage characteristics:

-

Large-scale power grids often cannot fully cover these areas.

-

The sites are vast in area.

-

Loads are diverse in size and type.

-

Many loads are temporary, tied to short project cycles—drilling stations usually operate for 6 months to 2 years.

-

Loads frequently cause power surges and voltage fluctuations.

Currently, most oilfields rely on diesel generators, which come with high costs, noise pollution, and reduced living quality. To address these issues, there are generally two main microgrid approaches:

-

Renewables + Storage + Diesel hybrid microgrids (wind/PV as primary, diesel as backup).

-

Diesel + Storage microgrids (diesel as primary, storage as support).

The key application scenarios for microgrid energy storage in oilfields include:

1. Wind-Solar-Diesel-Storage Microgrids

For islands or remote sites beyond the reach of public grids, long dedicated transmission lines are costly, and pure diesel power means high fuel costs, large losses, heavy smoke, and noise pollution. By deploying a wind-PV-diesel-storage microgrid, sites can achieve self-sufficient, greener, and more economical power.

2. Construction Power in Off-Grid Areas

For small-scale construction in areas without grid access, diesel generators are common but face issues of high fuel costs, severe noise, and low efficiency at partial load. Energy storage can replace diesel to provide temporary power, or work in hybrid mode to optimize diesel efficiency.

3. Backup for Critical Loads

In critical scenarios, even short outages can cause major financial losses or operational issues. Integrated on/off-grid switching storage systems can safeguard these loads, ensuring continuous power with high reliability and efficiency, by operating in parallel with the existing supply lines.

4. Green Energy for Drilling Operations

When drilling rigs or pumpjacks descend, gravitational energy is converted into kinetic and electrical energy, often wasted as heat via resistors. By connecting a PV+storage system to the VFD DC side, excess energy is stored rather than wasted, improving energy efficiency while leveraging solar power for green, low-carbon operations.

5. Mobile Energy Storage Power Trucks

Construction sites may face unexpected power failures, jeopardizing worker safety and key equipment. A mobile energy storage truck, built on a truck chassis with LiFePO4 batteries, BMS, inverters, and energy management systems, features modular design, seamless on/off-grid operation, and real-time monitoring—ideal for emergency power and temporary backup.

6. Integrated Solar-Diesel-Storage Microgrids

At large oilfield sites with high loads, diesel remains the primary power source. Adding PV + storage cuts fuel consumption and offers quiet, high-quality power for living quarters, improving overall life on site.

Chapter 1: Small Wind-Solar-Storage Off-Grid Systems

This system combines PV panels (with movable frames), PV controllers, wind turbines, wind controllers, standard and VFD inverters, storage batteries, and loads—using DC coupling to gather energy at the DC bus.

-

Standard inverters drive typical loads like lighting and offices.

-

VFD inverters drive inductive loads such as pumpjacks or water pumps.

How it works:

-

During the day, PV and wind generate power for direct loads, storing excess in batteries.

-

When PV and wind are insufficient, batteries discharge to power loads.

-

During prolonged cloudy or low-wind periods, a diesel generator is manually started to supply power.

Typical design example:

-

For a site with an 11kW pumpjack (estimated at 150kWh/day) and 8kW for worker living quarters (20kWh/day), with >24h autonomy in cloudy weather:

-

A DC-coupled system with an 18.5kW VFD inverter, 34.8kWp PV (60 x 580W panels), and two 5kW wind turbines is used.

Applications:

These systems range from 10-100kW with 10-500kWh storage, flexible for daily loads under 3000kWh. PV and wind complement each other well—more PV in summer, more wind in winter.

Chapter 2: Medium-Power Diesel+Storage Microgrids

Primarily for areas without grid access, these systems coordinate diesel generators with storage:

-

Storage serves as diesel backup, improves generator load rates, reduces unit fuel consumption, and solves noise issues at night.

-

Smart controls enable seamless switching, ensuring power stability.

Scenarios:

-

24-hour well workovers:

-

At night, storage powers living areas; during operations, storage helps handle heavy motor starts, reducing overload trips and dual-generator fuel use.

-

-

Night-only operations:

-

Storage independently supplies loads, sized for short intermittent starts of control rooms or boosted to handle frequent motor inrush.

-

-

Low-load sites (<20kW):

-

Storage raises diesel load rates, significantly cutting fuel costs and night noise.

Example:

-

Three camps, each with ~2kW at night. Day work may run an 11kW mixer and 7kW circulation pump.

-

A 100kW/233kWh system provides ~10h at 20kW, charging during the day via diesel.

Applications:

100kW-1MW systems with 200kWh-2MWh storage, integrated PCS, EMS, BMS, cooling, and safety. Supports 10-unit parallel expansion, ideal for diesel-heavy or unstable grid regions.

Chapter 3: Mobile Storage Trucks

Built on pickup or truck platforms (JMC, Dongfeng, Isuzu, Nissan), with LiFePO4 batteries, inverters, and smart control—features:

-

National-standard DC charging, plug-and-play outlets, supports 100% unbalanced 3-phase loads.

-

Agile, quickly deployable, suitable for:

-

Live-line work

-

Emergency backup at critical sites

-

EV rescue

-

Rural grids, logistics, environmental projects, power maintenance, telecom 5G upgrades, and oil/gas welding.

Chapter 4: Large Solar-Diesel-Storage Microgrids

These combine PV, diesel gensets, storage, and energy management.

-

PV generates DC, inverted to AC for loads or the grid. The grid or diesel can also charge batteries via bi-directional converters.

-

The diesel serves primarily as backup, minimizing runtime to save fuel.

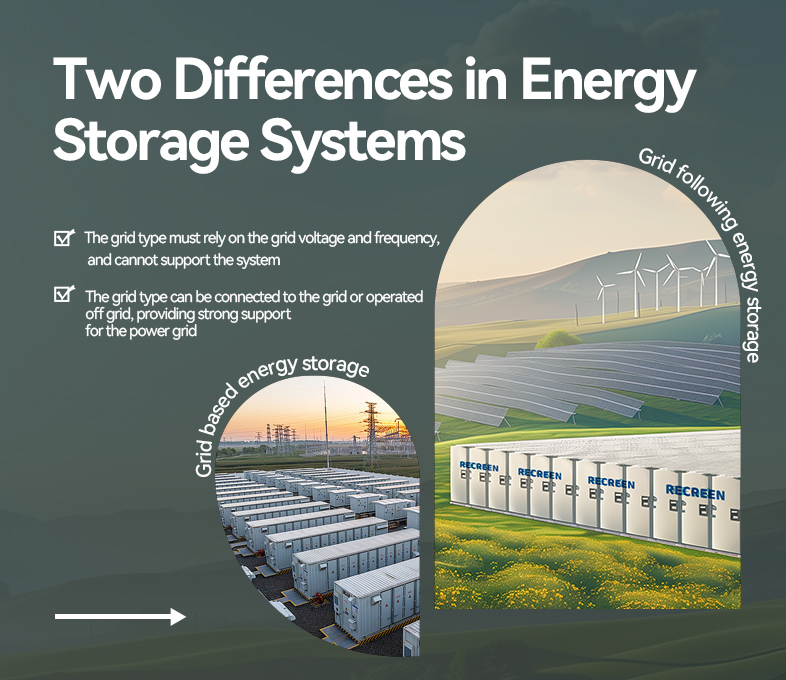

Advantages of AC coupling:

-

Works for on-grid/off-grid with flexible modes:

-

PV + grid/diesel joint power

-

“Self-consumption with excess to grid or storage”

-

Peak shaving with PV+storage during high rates

-

-

Configurable with string or central inverters, multiple brands, unequal sizes.

-

High efficiency: up to 96% direct use of PV via inverters.

-

Strong load capacity—can handle 3-5x motor inrush with combined inverter outputs.

Applications:

500kW-5MW systems with 1-20MWh storage, using containerized batteries, suited for high diesel reliance, large price gaps, or high-rate areas.

Example:

-

A site using ~4800kWh/day, with 15kW/200kW diesel gens, designed with:

-

1.4MW PV (2400 x 580W panels)

-

3000kWh storage + 1MW PCS

-

Total cost ~8.5M RMB, ROI ~4 years, saving ~1.8M RMB annually thereafter.

-

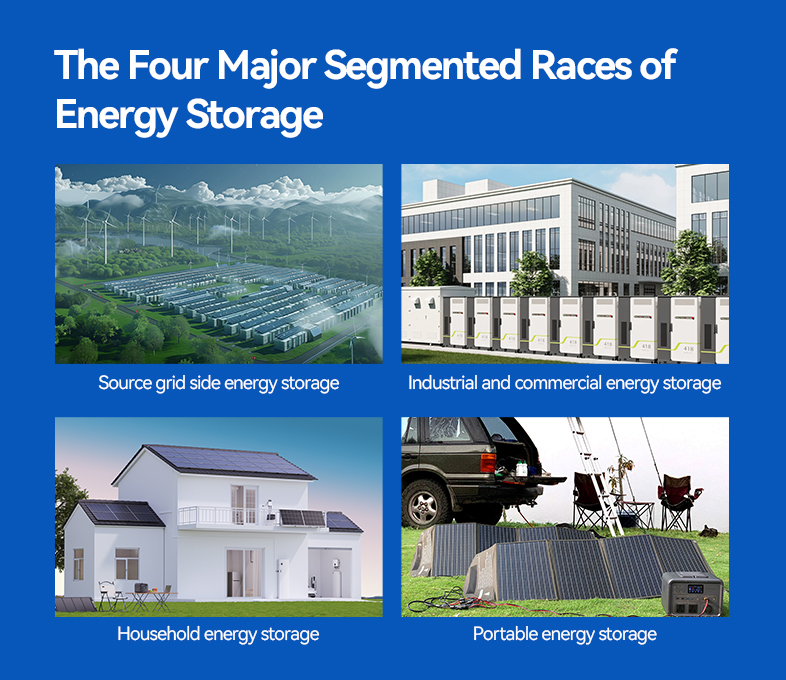

Summary: Market & Competitive Insights

Today’s PV+storage industry is crowded, low-margin, and over-supplied. Only companies close to end-users, solving integration and consumption challenges with complete, reliable solutions, will lead the market transformation.