Energy storage batteries and power batteries differ in several aspects, primarily including the following points:

- Application Scenarios

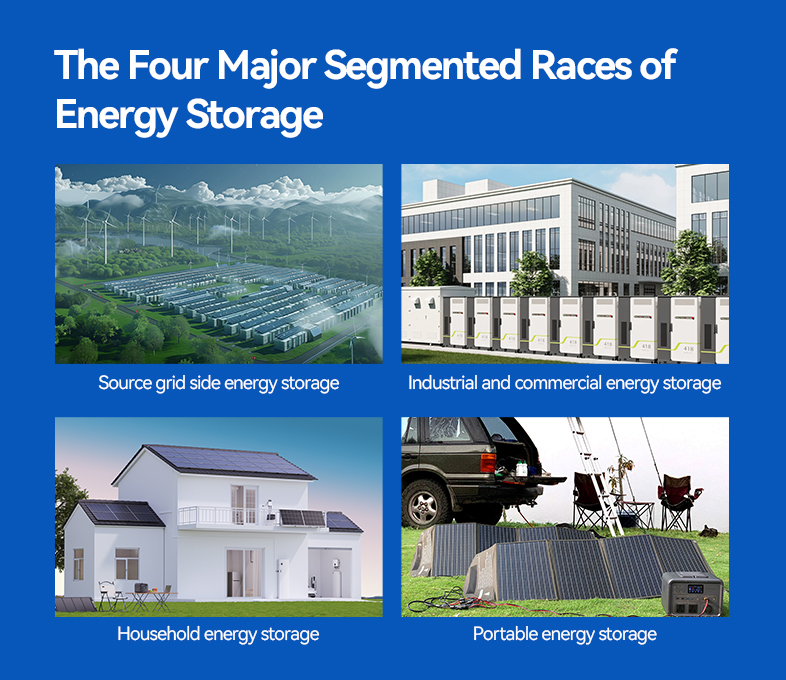

- Energy Storage Batteries: These batteries are used to store energy by converting electrical energy into chemical energy for later release when needed. They are widely used in grid energy storage, industrial and commercial energy storage, as well as household energy storage. Their main task is to balance power supply and demand and improve energy utilization efficiency.

- Power Batteries: This refers to batteries used to store and provide power for electric vehicles, plug-in hybrid vehicles, and other vehicles. They are the “heart” of electric vehicles and electric bicycles, providing a continuous and stable source of power for these mobile devices.

- Charge and Discharge Characteristics: The Balance of Speed and Endurance

- Energy Storage Batteries: Typically, energy storage batteries have lower charge and discharge rates and do not require high speed; they emphasize long cycle life and energy storage efficiency.

- Power Batteries: These batteries must support high charge and discharge rates to meet the high power output needs for vehicle acceleration and climbing, requiring them to release a large amount of electrical energy within a short time.

- Energy Density and Power Density: Pursuing Extreme Performance

- Power Batteries: High energy density and high power output are essential to meet the range and acceleration requirements of electric vehicles. They often use more active electrochemical materials and compact battery structures, allowing them to deliver large amounts of energy quickly and achieve rapid charge and discharge.

- Energy Storage Batteries: Typically do not require frequent charge and discharge operations, so their requirements for energy density and power density are lower. They focus more on power density and cost and often use more stable electrochemical materials and more relaxed battery structures that can store more energy while maintaining stable performance over a long operational period.

- Lifespan and Characteristics: The Test of Durability

- Energy Storage Batteries: Generally have lower energy density and may be designed with automatic charge/discharge functions to adapt to specific energy demand patterns in some applications.

- Power Batteries: These are long-life batteries characterized by high energy density, high rate cycle usage at partial states of charge, and can be reused across a wide temperature range (-30 to 65°C) while maintaining high performance.

- Cost: Balancing Economy and Performance

- Energy Storage Batteries: Due to differences in application scenarios and performance requirements, they often emphasize cost control to achieve economic viability for large-scale energy storage systems.

- Power Batteries: While ensuring performance, efforts are constantly being made to reduce costs; however, they remain relatively high.

- Safety: The Rigor of Protective Measures

- Power Batteries: Often focus on simulating extreme conditions during vehicle operation, such as high-speed collisions and overheating due to rapid charge and discharge. The installation position of power batteries in vehicles is relatively fixed, and safety standards mainly emphasize overall vehicle collision safety and electrical safety.

- Energy Storage Batteries: With larger system scales, they pose a higher risk in case of fire, so fire safety standards for energy storage batteries are usually stricter, covering aspects like response time of fire extinguishing systems and the types and amounts of extinguishing agents used.

- Manufacturing Process: Meticulously Polished Craftsmanship

- Power Batteries: The manufacturing process requires high environmental standards, strict control of humidity and impurity content to avoid affecting battery performance. The production process typically includes electrode preparation, battery assembly, liquid injection, and formation, with the formation process significantly impacting battery performance.

- Energy Storage Batteries: The manufacturing process is relatively simpler but must also ensure battery consistency and reliability. During production, attention must be paid to controlling the thickness and compaction density of electrodes to improve energy density and cycle life.

- Material Selection: Dual Consideration of Performance and Cost

- Power Batteries: They need to have high energy density and good rate performance, so higher-capacity cathode materials such as high-nickel ternary materials and lithium iron phosphate are often chosen, while anode materials usually include graphite. Additionally, power batteries have higher requirements for electrolyte ionic conductivity and stability.

- Energy Storage Batteries: They place greater emphasis on long cycle life and cost-effectiveness, so cathode materials may include lithium iron phosphate, lithium manganese oxide, etc., while anode materials might utilize lithium titanate. Regarding electrolytes, the ionic conductivity requirements for energy storage batteries are relatively lower, but there is a higher demand for stability and cost.

In summary, although energy storage batteries and power batteries are both types of batteries, they exhibit significant differences in design, material selection, and manufacturing processes due to their different application scenarios and performance requirements. As technology continues to advance, these differences may gradually diminish, and more new types of battery technologies and application scenarios may emerge.